Case Study: Ndustrial Expands Globally With Help From JFrog Connect

Overview

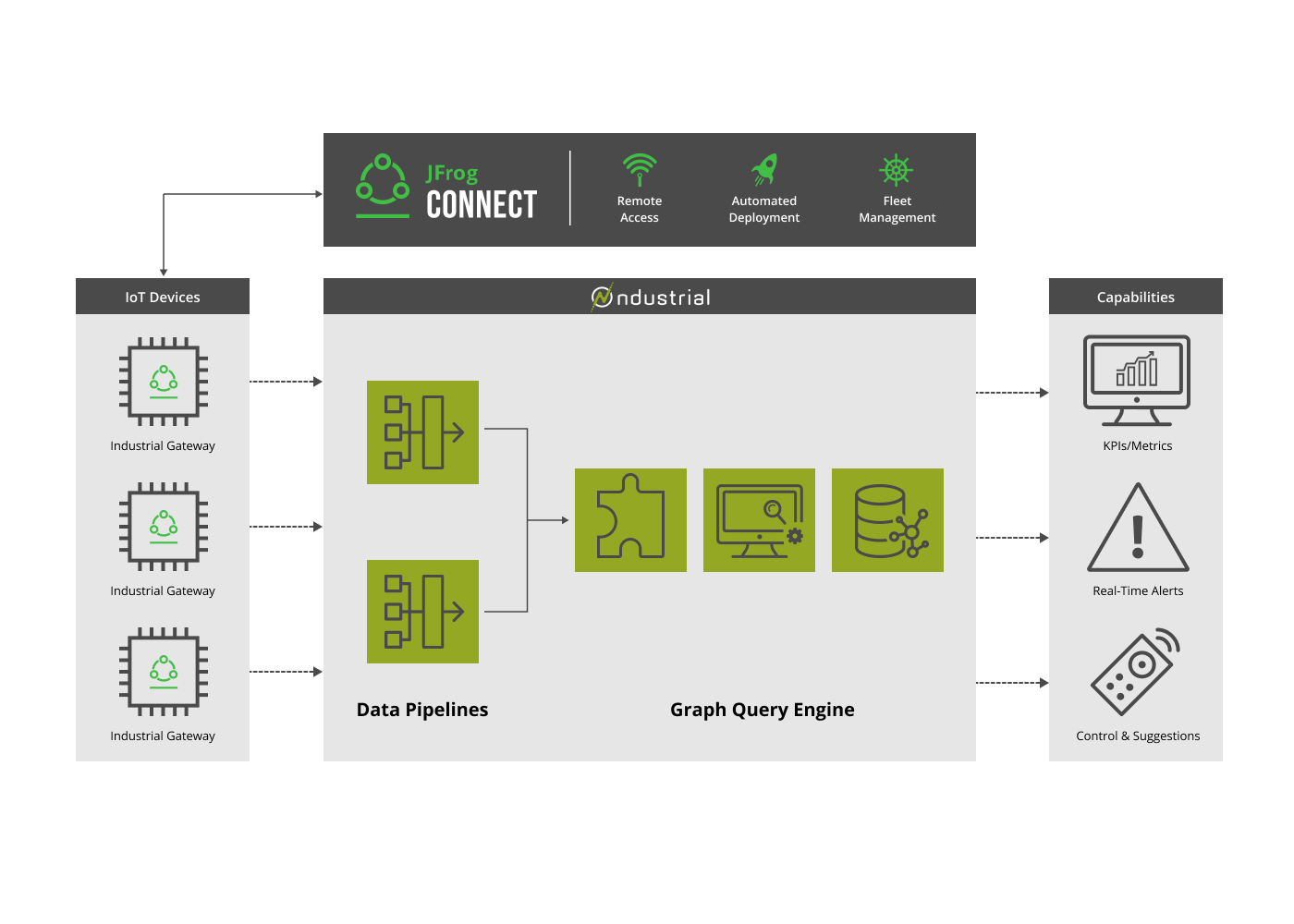

Ndustrial uses JFrog Connect to create innovative Internet of Things solutions for industrial operations that ultimately saves customers tens of thousands of dollars a day in energy costs.

Company

Ndustrial has helped clients avoid over $100 million in potential energy spend. They merged computer science and industrial engineering to build a real-time energy intelligence platform. Today, Ndustrial delivers the industry’s only “production-first” Energy Intensity platform, enabling companies to maximize production efficiency while minimizing energy costs.

Challenge

Ndustrial has been serving clients in the U.S. and Canada since 2011, and they’re now expanding globally. With that comes new challenges. With facilities being added worldwide, Ndustrial needed a way to automate their deployment process for IoT devices. They also needed a way to support ongoing customer needs remotely.

Every industrial facility is unique. Ndustrial deploys software updates to sites with varying equipment and controllers, VPNs, firewalls, and networking requirements, which makes deployment very challenging.

More importantly, in an industrial environment, remote access isn’t a trivial task. Client cybersecurity requirements are extremely stringent, since any incidents could have real safety implications for facility personnel.

Ben Fussell, a systems integration engineer, takes these responsibilities very seriously. He needed a solution with built-in security features that could help Ndustrial’s team better serve hundreds of mission-critical facilities around the world.

Solution

Before leveraging tools like JFrog Connect and Docker, Ndustrial’s edge software deployment process was manual and laborious. The typical workflow included connecting to customer VPNs, manually transferring program binaries to the edge device, and manually starting the new application. Ndustrial now uses JFrog Connect as part of their unique toolset for automated deployment, remote monitoring and troubleshooting, and remote access.

JFrog Connect and featured Connect tools like parameterized update flows, alerting webhooks, and API allowed Ndustrial to develop containerized software connecting industrial gateways worldwide directly to their data platform.

This access allows Ndustrial to automate the deployment process, and ultimately scale edge deployments and support customer needs much faster. “The process of committing code and having it show up on edge devices across the world is completely automated,” said Ben Fussell, Systems Integration Engineer, Ndustrial.

JFrog Connect also allows Ndustrial to remotely test and troubleshoot edge devices by implementing temporary, secure remote connections. Device health alerts around communication and resource usage also help the team proactively pursue issues to help minimize customer downtime, which is very important in an industrial environment.

“JFrog Connect, for me, is really a scaling tool so I can deploy edge IoT integrations much quicker and manage them at a larger scale. There’s less manual, one-off intervention when connecting to different customer sites with different VPNs and firewall requirements,” Fussell added.

Result

With the help of JFrog Connect and over-the-air software updates, Ndustrial can now support the rapid expansion of existing clients’ global portfolios of facilities. They can also bring on new clients without a major investment in travel and personnel.

Ndustrial is currently expanding using JFrog Connect into roughly 50 facilities, from Europe to Asia to Australia. Customers such as the world’s leading cold storage company and the world’s largest mechanical tire recycler are trusting Ndustrial to help optimize their operations.

Ndustrial’s remote access sometimes includes the ability to write code back to IoT devices for automated load control. This helps to greatly simplify clients’ experience with programs like load shifting and demand response.

In some cases, users can substantially reduce energy costs with nothing but a simple text message of approval. Customers have saved over $20,000 a day using this approach.

It’s exceedingly rare for mission-critical facilities to trust a third party with such a powerful responsibility as remotely shutting down their equipment. Ndustrial has earned that trust in some of the world’s leading industrial operations, in part thanks to the built-in features in JFrog Connect.

“I definitely think JFrog helps with initial deployment, but the support and maintenance aspect, the ongoing time it takes to troubleshoot and fix issues and redeploy patches, is honestly even more valuable because that saves us from having to take trips to job sites.”

– Ben Fussell, Systems Integration Engineer, Ndustrial

Download the PDF version of this Case Study here.

INDUSTRY:

Industrial Software Development

PROBLEM:

- Ndustrial’s global expansion made manual deployment overly cumbersome

- Ongoing support would have required far more travel and expense

- Unique requirements of industrial facilities made it hard to find an appropriate solution

RESULTS:

- Committing code and deploying to edge devices worldwide is completely automated

- Remote monitoring allows issues to be addressed proactively, averting facility downtime\

SOLUTION:

JFrog Connect

Watch the Full Video: Ndustrial + JFrog Connect

Video Case Study Table of Contents:

- 00:00 Introduction

- 00:08 Background and JFrog Connect Benefits

- 01:06 Use Case

- 03:15 Favorite Features

- 04:08 Cost Savings

Questions about JFrog Connect? Email contact@jfrogconnect.com or visit https://bit.ly/3GIqIIW.